Your Hot rolling process animation images are available in this site. Hot rolling process animation are a topic that is being searched for and liked by netizens now. You can Get the Hot rolling process animation files here. Download all royalty-free vectors.

If you’re searching for hot rolling process animation pictures information related to the hot rolling process animation keyword, you have pay a visit to the right blog. Our website always gives you hints for refferencing the highest quality video and image content, please kindly surf and locate more enlightening video articles and images that fit your interests.

Hot Rolling Process Animation. The hot metal is converted into steel through a steelmaking process called the ld process. Seamless.exe see animation tapany udomphol 56. The reeled tube is then sized by a sizing mill to the specified dimensions. This allows steel sheets to be made in larger, thicker sizes, ideal for the manufacture of railway rails, large beams, or girders.

From venturebeat.com

From venturebeat.com

Hot metal from the blast furnace is added by pouring from a ladle through a trough positioned Seamless.exe see animation tapany udomphol 56. These cleaned (pickled) products are then passed through rollers at room temperature. This method uses powerful presses and/or hammers and relies on the shape of the dies, which are essentially cast impressions of the end product. This process completes the hot working of the tube. For example, we provide solutions that meet customer needs such as the slit rolling system and the high speed mill (40m/s) which increase productivity, the hot direct rolling system which is directly connected with a continuous caster, not via a reheating furnace, and thereby greatly reduces the energy consumption, the water quenching system which helps in enhancing the.

This process completes the hot working of the tube.

The hot metal is converted into steel through a steelmaking process called the ld process. Even worse, you import the excel file on the ui thread, which blocks any animation and freezes the complete ui. The hardness obtained by hot rolling is less comparatively that of obtained by cold rolling. Other manufacturing processes like casting where liquid metals are poured into a mold and the operation are carried but when we talk about forging, the operation performs on metals. The reason for this is regardless of the substrate uniformity, the precision gap between the coating knife and the backing roll will result in a total product thickness which is extremely uniform. Hot rolling processcold rolling processgrain flow in hot rolling processgrain flow in cold rolling processe4educationjoin our official telegram channel :

Source: venturebeat.com

Source: venturebeat.com

And, this process is carried out below the recrystallization temperature that is room temperature. Even worse, you import the excel file on the ui thread, which blocks any animation and freezes the complete ui. The reeled tube is then sized by a sizing mill to the specified dimensions. Seamless.exe see animation tapany udomphol 56. The hot metal is converted into steel through a steelmaking process called the ld process.

Source: partscasting.com

Source: partscasting.com

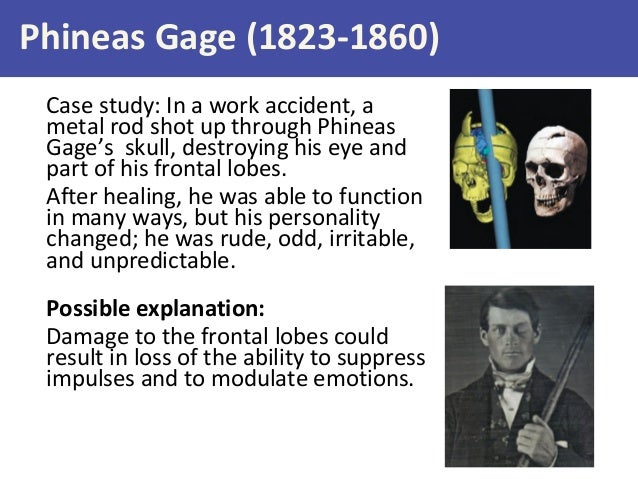

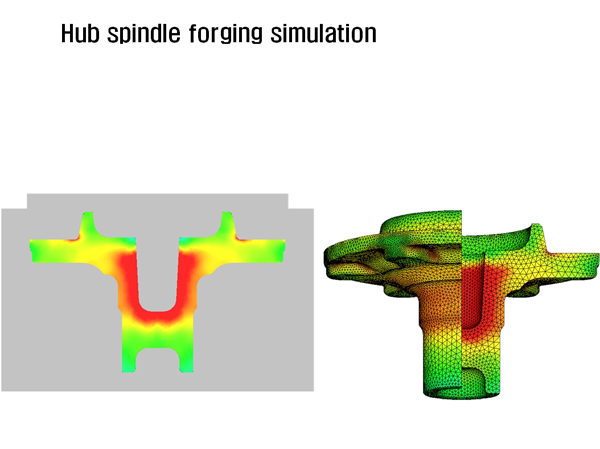

Forging is a manufacturing process in which we obtain different shapes and sizes of a metal by the operation of hot and cold forging. The hot metal is converted into steel through a steelmaking process called the ld process. The action of the rolls causes the metal to flow over and about the mandrel to create a hollow pipe shell. The hot rolled articles are first immersed in a weak solution of sulphuric acid to remove the scale and washed in water, and then dried. And, this process is carried out below the recrystallization temperature that is room temperature.

Source: afdex.com

Source: afdex.com

Hot rolling refers to the process of rolling steel at a temperature typically above 900 °c, greater than its recrystallisation temperature. Scrap is charged to the furnace through doors in the furnace front. The reason for this is regardless of the substrate uniformity, the precision gap between the coating knife and the backing roll will result in a total product thickness which is extremely uniform. One of the most common processes is a type of hot forging known as impression die forging (also known as closed die forging), which is the process utilized by rex forge. Hot metal from the blast furnace is added by pouring from a ladle through a trough positioned

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title hot rolling process animation by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.